Pneumatic Vacuum Elevators

Operation

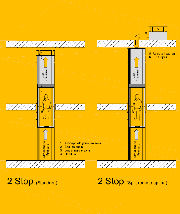

The vacuum elevator combines a smooth vertical cylinder with a coaxial car that moves up and down through air suction. The principal operation of the elevator is based on the ascending push generated by the difference between the atmospheric pressure on the top of the car and the atmospheric pressure under the car. The depression (vacuum) required to lift the car is achieved by turbines operating as an exhaust fan, which is located at the top of the elevator.

The roof piston gear surrounded by a sliding air-tight seal allows an almost frictionless movement and hoists the car due to the pneumatic depression (vacuum) generated on the upper part. This provides the hoisting force, since the atmospheric pressure is higher than that inside the upper shaft.

A valve regulating inflow of air in the upper part of the shaft controls the pneumatic depression (vacuum), enabling descent and control of the car speed.

The lower part of the shaft is open to ensure the free movement of air so as to create normal atmospheric pressure.

The air suction process simply consists of a suction device that sets the difference in pressure between the atmospheric and that inside the shaft which is limited by the piston, the side walls and the upper end. In this way, the portion of shaft below the piston and the interior of the car remain at atmospheric pressure.

At each floor/level, the perimeter seals on the door are self-sealing due to the action of the atmospheric pressure.

The car has locking devices to stop at the upper and lower limits of travel.

A safe braking device (chute) made up by a diaphragm or piston located on the roof of the elevator car activates in case of atmospheric pressure in the upper part of the piston, thus returning a passenger safely to the ground floor.